High-Quality Custom Screen Printing for Team Apparel

High-Quality Custom Screen Printing for Team Apparel

Blog Article

Exploring the Art of Display Printing: A Comprehensive Overview to Tee Printing Techniques

When you enter the globe of display printing, you're going into a domain name where creative thinking meets craftsmanship. It's not practically slapping ink on textile; it's a meticulous procedure that needs the right tools and techniques. As you discover numerous techniques, you'll discover just how to develop attractive t-shirt layouts that stick out. What are the necessary aspects you need to master prior to you can really make your mark?

The Essentials of Display Printing: Comprehending the Process

Display printing, frequently called serigraphy, is a flexible technique that allows you to transfer designs onto different surfaces. To begin, you'll initially need to develop a stencil, which functions as the foundation for your layout. This involves using a light-sensitive solution to a screen and exposing it to light, where your art work blocks the light from hardening the emulsion.

You then apply ink on top of the display and use a squeegee to push the ink with the pattern onto the surface area below. Comprehending these fundamental steps sets the phase for creating dynamic, enduring layouts via the art of display printing.

Necessary Tools and Products for Display Printing

To obtain begun with screen printing, you'll require some key tools and products. From the right devices to the inks and emulsions that bring your designs to life, each element plays a crucial duty. Allow's discover what you need to be successful in this imaginative procedure.

Display Printing Devices

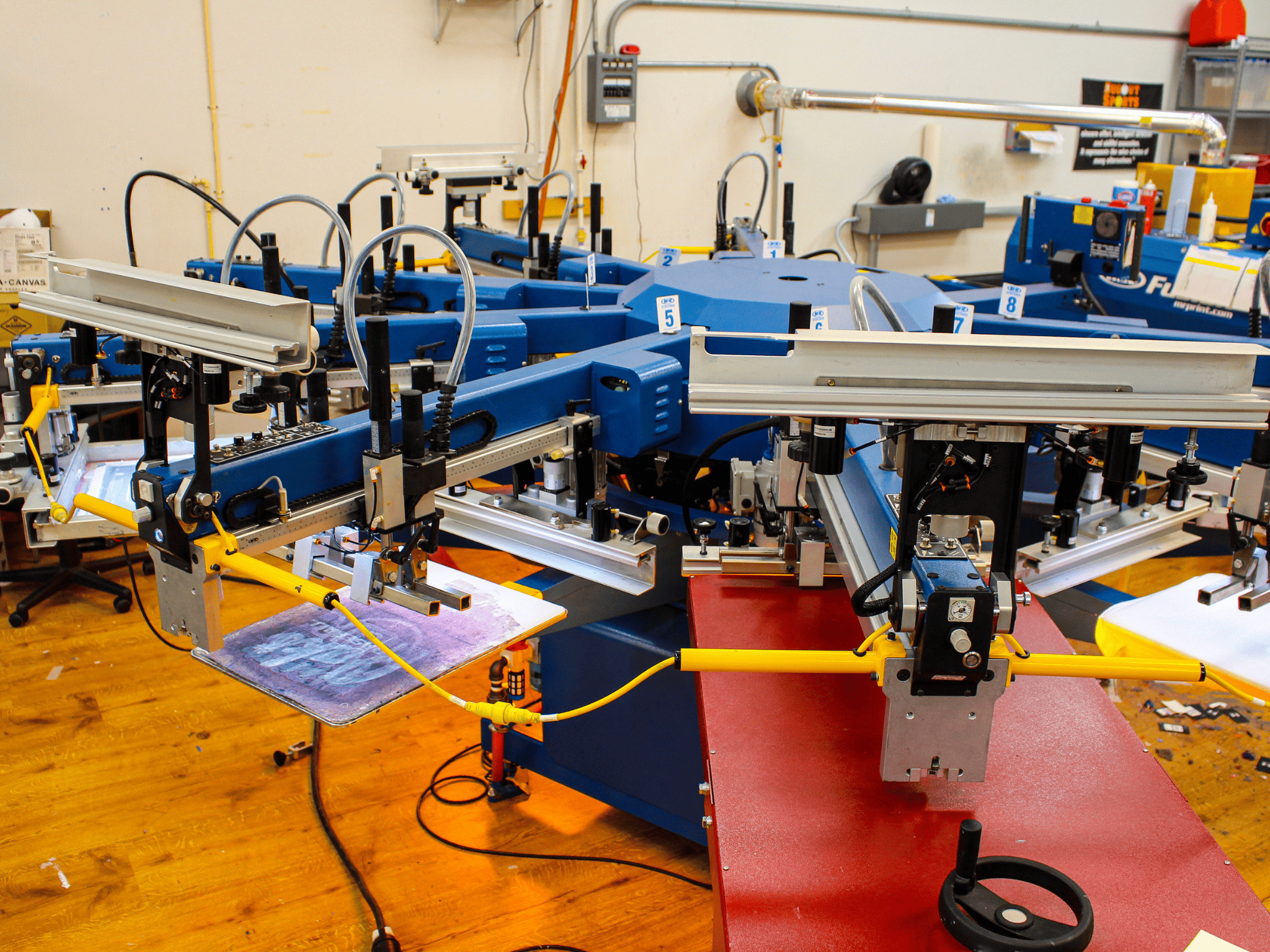

While diving into the globe of screen printing, you'll find that having the right tools is crucial for achieving high-quality outcomes. Start with a strong screen printing framework, which holds the mesh that transfers ink onto your fabric. With these devices, you're well on your means to mastering screen printing!

Inks and Solutions

Choosing the right inks and emulsions is essential for attaining vivid and sturdy prints. You'll wish to pick inks based on your preferred coating and textile type. t-shirt printing. Plastisol inks are preferred for their convenience of use and excellent opacity, while water-based inks offer a softer feel and are a lot more environmentally friendly

Solutions act as a light-sensitive layer on your displays, vital for creating sharp stencils. Make sure to select a top notch solution that matches your ink type; some emulsions function much better with plastisol, while others are excellent for water-based inks. Correct curing is additionally crucial; it assures the ink sticks well and takes on washing. By buying the right inks and solutions, you'll elevate your screen printing video game substantially.

Devices for Application

After selecting the appropriate inks and solutions, the following step is collecting the devices and materials that will certainly assist you use them properly. You'll need a sturdy display, preferably made from aluminum or wood frameworks, in addition to a great mesh for proper ink transfer. A squeegee is crucial for applying stress and spreading out ink evenly throughout the screen. Do not forget a reputable exposure system to aid you create crisp patterns. Additionally, a registration system will certainly assure your designs line up completely on each t-shirt. You'll additionally want a washout terminal for cleaning up displays after use (t-shirt printing). Finally, buy top quality gloves and aprons to maintain your work area clean and shield on your own from ink stains. With these devices, you'll be well-equipped for successful screen printing!

Conventional Screen Printing Techniques

Typical display printing methods have stood the examination of time, showcasing the art and workmanship behind this popular technique. You'll typically begin with a stencil made from a great mesh material extended over a frame. This mesh permits ink to go through while blocking locations you intend to continue to be unprinted. As soon as you've prepared your layout, you'll apply a light-sensitive emulsion to the screen and expose it to a light resource, hardening the emulsion where you want ink to circulation.

After rinsing the unexposed solution, you're left with a stencil. You'll after that put your display on the t-shirt, use ink ahead, and utilize a squeegee to push the ink through the mesh. This procedure can be duplicated for several colors, requiring separate screens for each. The result? Dynamic, durable styles that display your creativity. Grasping these strategies gives you a solid foundation for all your screen printing ventures.

Modern Innovations in T-Shirt Printing

Today's tee shirt printing landscape is humming with exciting developments that are changing how you produce layouts. With developments in electronic printing, environment-friendly products, and advanced modification technologies, you can create one-of-a-kind, sustainable t-shirts like never ever in the past. Let's explore these modern-day strategies and see how they enhance your printing experience.

Digital Printing Innovations

As digital printing technology has actually evolved, it's transformed the landscape of Tees printing, using you unprecedented precision and creativity. Direct-to-garment (DTG) printing enables you to publish directly onto material, making it ideal for tiny recommended you read runs or customized designs. With innovations in ink top quality, you can anticipate sturdiness and washability that matches screen printing.

Eco-Friendly Materials Usage

While exploring contemporary technologies in T-shirt printing, you'll discover a growing emphasis on environmentally friendly materials that focus on sustainability without compromising quality. Furthermore, water-based inks are getting appeal, as they create less dangerous overflow compared to traditional solvent-based inks. These inks are not only much safer for the atmosphere but likewise offer dynamic colors and soft textures on fabric.

Modification Technologies Development

With the rapid advancement of modern technology, personalization in T-shirt printing has actually transformed significantly in recent times. You now have accessibility to electronic printing methods like Direct-to-Garment (DTG) and Dye-Sublimation, which permit brilliant colors and complex designs. These technologies make it simple to develop unique items without the high costs of standard screen printing. Furthermore, online design systems empower you to picture your ideas prior to printing. You can experiment with various designs, colors, and positionings at your fingertips. Therefore, you can satisfy specific tastes and patterns faster than ever before. Accepting these modern innovations, you can elevate your Tee shirts designs and use customers one-of-a-kind items that absolutely reflect their personalities.

Picking the Right Ink for Your Designs

Exactly how do you select the ideal ink for your screen printing designs? If you're publishing on artificial products, plastisol inks supply toughness and vivid shades.

Following, assume about the finish you desire. Matte inks provide a subtle appearance, while glossy inks can add a striking sheen. If you're going for eco-friendliness, select soy-based or water-based inks, which are better for the environment.

Don't ignore color mixing; some inks can be blended to produce unique tones. Examine your inks on example materials to verify compatibility and look before beginning your main job. Ultimately, the best ink can make a substantial difference in the top quality and durability of your layouts, so choose carefully!

Tips for Creating Stunning Tee Shirt Designs

Creating magnificent tee shirt designs begins with a clear idea that reverberates with your target market. Keep in mind, more helpful hints simplicity frequently works ideal; chaotic designs can perplex visitors.

Include typography that reflects the personality of your brand name-- select fonts that are readable yet stylish, and blend them wisely. Focus on placement; the style must stream naturally with the tee's shape.

Trying out different designs, such as classic or modern-day, to locate what fits ideal. Don't shy away from using adverse area effectively; it can produce a striking visual effect.

Finally, get comments! Share your styles with buddies or prospective customers to assess their responses (t-shirt printing). Their insights can direct you in fine-tuning your work, guaranteeing your final design is not only spectacular yet likewise market-ready

Fixing Typical Display Printing Obstacles

When you run into obstacles in screen printing, identifying the origin can make all the difference. Examine your display for proper stress and confirm your emulsion is fully cured if you notice incomplete prints. For smearing or fuzzy photos, it might be due to incorrect ink viscosity or not enough curing time; readjust your ink or cure settings as necessary.

If you're managing shade mismatches, ascertain your ink blending ratios and verify your screens are tidy and cost-free of deposit.

Finally, if you're experiencing training or peeling, think about the kind of textile you're using and the warmth applied throughout treating; various materials call for details inks and temperature levels. By dealing with these usual problems systematically, you'll improve your outcomes and increase your confidence in display printing. Maintain trying out, and don't think twice to get to out to fellow printers for ideas and suggestions.

Often Asked Concerns

Can I Evaluate Publish on Fabric Aside From Tees?

Absolutely, you can screen print on various fabrics besides tees! Consider products like shopping bag, hoodies, or perhaps tablecloths. Just ensure you're utilizing the appropriate find more ink and tools ideal for the material type.

How Do I Tidy and Maintain My Display Printing Tools?

To cleanse and maintain your screen printing devices, routinely clean screens with water and proper cleaners, inspect squeegees for damages, and shop every little thing in a completely dry, dust-free environment to prolong its lifespan and ensure high quality prints.

What Is the Typical Expense of Beginning a Screen Printing Business?

Beginning a screen printing company typically sets you back between $2,000 and $10,000. You'll need equipment, supplies, and a workspace. It's important to spending plan wisely and prepare for extra costs as your organization expands.

Is Screen Printing Eco Friendly?

If you pick lasting products and eco-conscious inks,Display printing can be ecologically pleasant. By adopting ideal techniques and reducing waste, you can lower your impact while producing dynamic, high-grade prints that interest mindful consumers.

Exactly How Can I Promote My Customized Tee Designs Efficiently?

To promote your custom-made tee designs successfully, take advantage of social media sites platforms, collaborate with influencers, run targeted advertisements, and involve your audience with competitions or free gifts. Regular branding and high quality visuals will certainly attract even more consumers.

Checking out the Art of Display Printing: A Comprehensive Overview to Tee Shirt Printing Strategies

Start with a durable display printing structure, which holds the mesh that transfers ink onto your material. By spending in the ideal inks and solutions, you'll raise your screen printing video game substantially.

With improvements in ink top quality, you can anticipate longevity and washability that matches screen printing.How do you pick the best ink for your screen printing designs?

Report this page